High pressure oilfield pumps form the backbone of many operations that push fluids deep under the ground. Engineers pick and tune pumps to match tough field conditions and demanding service intervals.

A clear grasp of core features helps users pick the right unit and keep downtime low. Below are five key attributes that often separate reliable machines from ones that struggle on the job.

1. High Pressure Rating And Safe Operation

Pressure rating is the headline number that tells you how much force a pump can handle on a steady basis without giving up the ghost. Manufacturers test parts at staged pressures and publish both working pressure and burst thresholds so operators can plan safe margins and prevent nasty surprises.

Pumps run near their rated pressure for long stretches in many wells, which means engineering margins and quality control are not just paperwork but the difference between moving product and stopping the line. Good practice calls for pressure relief and safety valves placed where a single fault cannot cascade into a major incident.

Safe operation is closely tied to relief strategies and procedural discipline even when crews are under time pressure to hit a target. Regular inspection of gauges and periodic pressure testing catch creeping problems before they become headline events, and training that reinforces simple checks often saves hours of downtime.

Some systems offer redundant pressure sensors that feed a controller while other setups rely on analog gauges watched by a technician, and both approaches have their place on different sites. The trick is to match the pump and its pressure safeguards to the risk profile of the bore and the expected duty cycle.

2. Strong Materials And Corrosion Resistance

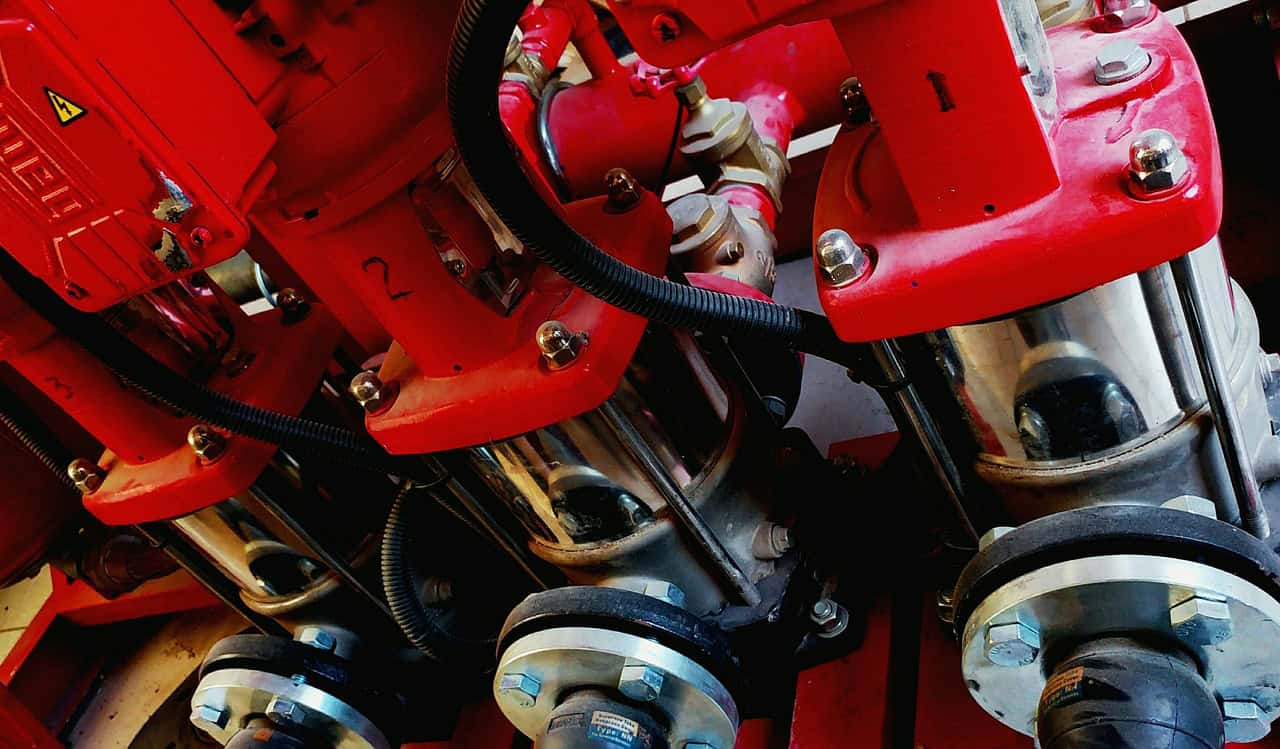

Material choice for pump bodies, shafts, and wetted parts directly affects longevity in sour service or saline environments where metal eats away at a steady clip. Stainless steels, specialty alloys, and ceramic coatings all play roles, and selecting the right combination means balancing upfront cost against long tail repair bills.

When fluids carry suspended solids, erosion joins corrosion as an enemy, so designers use tougher barriers or sacrificial sleeves to keep critical parts in one piece longer. Simple trades like replacing a soft metal spacer with a harder insert can extend run time a long way and reduce trips to the rig floor.

Surface finish and fit matter almost as much as metal grade since rough surfaces trap particles and create localized cells that speed corrosion and wear. Tight tolerances reduce vibration and stop tiny misalignments from growing into catastrophic failures that take an entire system offline.

In many cases component standardization across a fleet makes for faster swaps and a shorter parts backlog when trouble hits. Teams that think ahead about materials and spares usually find they are not constantly firefighting but instead running predictable maintenance cycles.

3. Advanced Sealing And Leak Control

Seals sit at the frontier where fluid pressure meets ambient conditions, and a failed seal can turn a contained process into a safety incident in short order. Modern pumps use mechanical seals with balanced faces, backup rings, and quench ports that keep contaminants out and reduce the chance of face damage when conditions spike.

Seal selection depends on temperature, pressure, and the chemical mix in the fluid stream, so one size rarely fits all and field feedback is valuable for tuning choices. Proper seal support systems that provide clean barrier fluid and controlled circulation are often the unsung heroes of long service life.

Leak control is not only about preventing product loss but also about keeping the surrounding equipment and crew safe from hazardous fluids that do not belong outside the line. Detecting small leaks early is a sensible strategy because small leaks are easier to fix and do not erode trust in the equipment.

Many sites add drip trays, visual inspection points, and simple diagnostic checks that cut repair time and expense. When a pump has robust sealing and an honest plan for finding and fixing leaks fast, the entire operation runs smoother.

4. Flow Capacity And Pump Efficiency

Flow capacity is what gets the job done when throughput targets are on the table, and a pump that cannot keep pace will force compromises elsewhere in the system. Engineers look at nominal flow curves and choose a model whose best efficiency point sits close to expected duty so the unit is not throttled into an inefficient corner.

System losses such as friction in piping and pressure drops across valves should be accounted for because they change the real load seen by the pump versus the textbook numbers on a spec sheet. A well matched pump spends less time running hard and more time delivering steady output while sipping energy.

Efficiency affects fuel or power consumption and the frequency of heat related wear, and a small gain in efficiency often returns several times that in operating savings over a campaign. Variable speed drives provide a tool to tune flow to need without making mechanical changes, and they can save energy when wells shift production levels.

For operators seeking dependable power for high-pressure applications, industrial diesel engines provide robust performance and easy on-site support. Smart choices combine the right pump curve, modest control features, and an eye on life cycle cost rather than just the sticker price.

5. Control And Diagnostic Systems

A modern pump is as much about information as motion since timely data helps crews catch trends before they become failures and allows remote teams to advise local crews without being on site. Basic controls manage start stop cycles and protect against overpressure, and richer setups add sensors for vibration, temperature, and small pressure deltas that signal early trouble.

When a diagnostics stack feeds clear alarms and historic logs, you can trace a problem back to its origin instead of guessing where things went wrong. That traceability shortens troubleshooting sessions and turns long nights into a couple of focused repairs.

Control goals range from keeping a unit running steady to protecting upstream and downstream gear from harm, and the right balance depends on site priorities and crew experience. Some operations prefer full automation with set points and automated shutdowns while others opt for conservative alarms that call for crew confirmation before a trip, and both approaches have pros and cons.

Data hygiene is part of the story because noisy inputs and unlabeled events erode trust in the system faster than a mechanical issue does. Teams that build simple, reliable feedback loops and keep the human element in the loop often get the best of both worlds.

Leave a Comment